The system includes not only the toilet itself but also a composting system and, where required, a conveyance method to transport solids and liquids from the toilet to a composting chamber.

- How a composting toilet system works

- The Different Types of Composting Toilet Systems

- Commode Batch Composting Toilet

- Chamber/Moldering Toilet

- Self Contained Composting Toilet System

- Continuous Composting Toilet systems

- Distributed / Off-Site Composting Toilet Systems

- Whole-House Composting Toilet Systems

- Off-Grid Composting Toilet Systems

- Important Design Considerations

- Conveyance Methods for Centralized or Split Systems

- Liquids Management

- Composting Toilet System Size & Cost

- Vermiculture / Tiger Toilets

- How Long to Compost & Safety

- Is a Composting Toilet System Right for You?

- Composting Toilet System FAQs

- Composting Toilet System FAQs

A composting toilet system is more than a toilet; it is a complete sanitation solution that safely turns human materials into nutrient-rich compost. While the term “human waste” is commonly used, we prefer toilet materials or humanure, because it’s only waste if you waste it, and a composting toilet system eliminates that waste!

Composting toilet systems can be built using local materials almost anywhere in the world, making them ideal for off-grid or environmentally conscious living. Understanding the components and how they work together is key to a successful, safe, and odor-free system.

How a composting toilet system works

A composting toilet system operates in four fundamental stages:

- Collection and Containment: The toilet captures both solids and liquids. Proper separation and containment at this stage is critical to ensure effective composting and odor control.

- Conveyance: If composting occurs in a separate chamber, solids must be transported. Conveyance methods vary from gravity-fed chutes, vacuum or micro-flush systems, to manual transport.

- Composting: Microorganisms and aerobic bacteria break down organic material, producing carbon dioxide, water, and a dark brown, nutrient-rich soil amendment. This process is aerobic, meaning oxygen must be available to the microbes for effective decomposition.

- Reuse or Disposal: Once fully composted, the material is safe to handle and can be used as a soil amendment in gardens or landscaping.

Self-contained systems often perform all four stages within the toilet unit itself, while centralized or split systems may require separate chambers and conveyance mechanisms. Regardless of system type, the end result is a mature, safe compost that bears no resemblance to the original materials.

The Different Types of Composting Toilet Systems

Composting toilet systems range from simple DIY units to complex, multi-user installations. Understanding the differences helps in selecting the right system for your needs. The main categories are:

- Commode Batch Composting Toilet: A simple system used worldwide for households or small installations.

- Chamber / Moldering Toilet System: A larger, below-floor system suitable for more frequent or multi-user applications.

- Continuous Composting Toilet System: A high-capacity system designed for continuous use.

These systems can also be categorized by their setup:

- Self-contained: Composting occurs entirely inside the toilet unit.

- Centralized: A separate chamber is shared among multiple toilets or users.

A fourth, less common variation, distributed composting toilet systems, involves off-site collection where materials are transported to a central facility for composting.

Commode Batch Composting Toilet

Batch composting toilets are the most accessible and widely recognized form of composting toilet. They are used globally, from urban apartments to remote off-grid homes, and can be constructed from locally available materials.

Joseph Jenkins’ Humanure Handbook outlines how batch systems can safely manage household toilet materials if supplemented with a managed compost pile or multiple bucket rotations.

Pros:

- Simple and reliable, with few moving parts

- Works without urine diversion

- Low-cost and scalable

Cons:

- Requires manual management

- Composting is time-intensive and requires multiple buckets or a compost pile

Chamber/Moldering Toilet

Chamber or moldering toilets are a scaled-up version of batch systems, with a large chamber beneath the floor. This allows for less frequent emptying and maintenance, making them suitable for higher-use scenarios.

Setup Options:

- Removable Bin: Replace the bin when full while the first matures.

- Twin-Chamber System: Fill one chamber while the other matures.

Pros:

- Reduced maintenance frequency

- Safe handling: solids are fully composted before contact

- Can accommodate multiple users

Cons:

- Larger bins require more physical effort to empty

- Urine diversion becomes more important due to volume

- Requires planning for access and space

Tips:

- Plastic or wheelie bins simplify handling

- Ventilation pipes (bioreactors) maintain aerobic conditions

- Raised platforms facilitate tipping compost into central piles

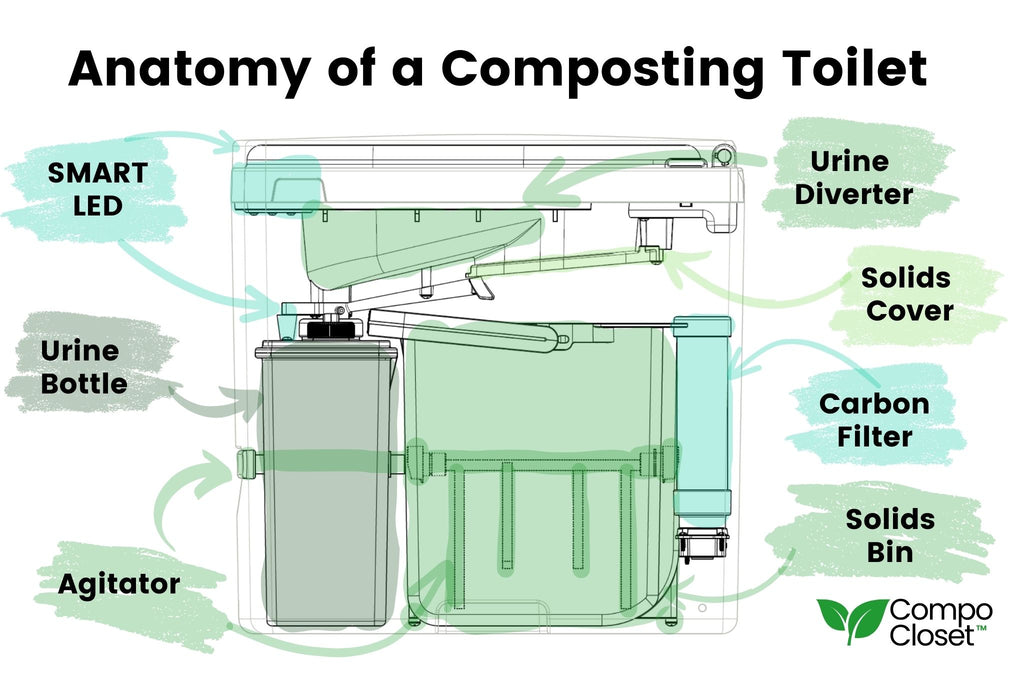

Self Contained Composting Toilet System

Self-contained composting toilets like Cuddy are among the most common types people think of when referencing these toilets. In these systems, all hardware for ventilation, agitation, and composting is built into the toilet unit itself. This makes them highly convenient for retrofitting spaces where plumbing or water supply is unavailable, such as temporary guest accommodations, tiny homes, or recreational vehicles.

Most self-contained units require a small amount of power for fans or motors to maintain proper airflow and agitation, but they are otherwise independent. The self-contained nature also ensures that solids and liquids are managed inside the unit, which simplifies installation and reduces the need for external infrastructure.

Because these units tend to be compact, they are generally intended for seasonal use or small numbers of users, making them a popular choice for cabins, tiny houses, or secondary bathrooms.

Pros:

- Compact and waterless

- Self-contained; minimal external infrastructure

- Ideal for retrofits and seasonal use

Cons:

- Limited capacity for multiple users

- Requires electricity for fans or agitation mechanisms

- Solids must be emptied manually into another location to fully compost

Continuous Composting Toilet systems

Continuous composting toilet systems are designed for full-time, multi-user applications. Unlike batch or chamber systems, continuous systems treat new material as it is added, eliminating the need to stop usage while composting occurs.

The most common design is an inclined grate, angled between 20–30 degrees. As materials compost, they gradually move down the grate until fully processed. These systems require infrequent emptying of fully composted materials and occasional breaking up or distribution of recently added deposits to prevent clogging the grate. Typically, this maintenance occurs every 2–3 months.

Because there is no physical barrier between treated and untreated materials, care must be taken during maintenance to avoid contamination. Continuous systems can accommodate multiple people using them full-time, making them suitable for larger households or centralized facilities.

Pros:

- Continuous treatment without stopping use

- Infrequent emptying compared to batch systems

- Handles multiple full-time users

Cons:

- High cost and complexity

- Maintenance can be unpleasant if problems occur

Distributed / Off-Site Composting Toilet Systems

Distributed composting systems are increasingly used in areas where conventional sanitation infrastructure is unavailable or impractical. In these systems, containers are used to collect toilet materials, which are then removed to a centralized facility for composting. Users receive a fresh container once the full one is collected.

This approach has been implemented successfully in countries such as Haiti and Madagascar, where container-based sanitation is both resilient and simple. The distributed system allows households to safely manage materials without building their own composting facilities, while centralized composting ensures proper pathogen reduction and quality of the final compost product.

Pros:

- Useful where infrastructure is limited

- Reduces household responsibility for compost management

- Centralized composting ensures safety and consistency

Cons:

- Requires regular collection service

- Less personal control over composting process

Whole-House Composting Toilet Systems

Whole-house composting systems are typically used in off-grid or environmentally conscious homes where traditional sewage connections are limited or unavailable. These systems allow multiple toilets to share a centralized composting chamber, improving efficiency and reducing individual maintenance.

Whole-house systems may be split systems, where the toilet pedestal is separate from the composting chamber, or centralized continuous systems, where a single large chamber handles all material. These systems can be retrofitted into existing homes, provided sufficient space and proper conveyance mechanisms are available.

Advantages:

- Reduces water consumption

- Minimizes handling of solids

-

Scalable for multiple users

Considerations:

- Proper conveyance mechanisms (gravity, vacuum, foam flush, micro flush, etc.)

- Access for routine maintenance

- Adequate space for compost maturation

Off-Grid Composting Toilet Systems

Off-grid composting toilet systems are completely feasible and often preferred for self-sufficient living. The main considerations are eliminating the need for power and water and ensuring a steady supply of carbon-rich cover materials.

A simple off-grid setup may include:

- A batch commode system with sufficient cover material so that ventilation fans are not required

- Several large compost piles that do not require energy inputs

- Rainwater collection to rinse solids buckets

- Optional ventilation via solar-powered or wind-powered fans

These systems emphasize simplicity, reliability, and independence, allowing households to manage toilet materials without reliance on external utilities.

Important Design Considerations

Designing a composting toilet system involves more than just choosing a toilet. Many practical factors are often overlooked, yet they can dramatically impact system usability, safety, and longevity. Careful planning ensures that routine maintenance is feasible and comfortable, especially for systems with larger chambers or higher usage.

For self-contained toilets, ease of removing the solids bin is critical. For example, when designing the Cuddy, one of the primary requirements was the ability to remove the solids bin (with agitator) without disassembling the entire toilet. Larger centralized systems require sufficient space to access service hatches and maneuver heavy bins, otherwise routine maintenance can quickly become a physically demanding task.

Proximity to the compost pile is another key consideration. Will the chamber be rolled or carried? If rolling, is a ramp required? If carrying, will one hand need to remain free? Is there sufficient lighting and space for safe handling?

Weight and Size of Solids Bins

The size and weight of the solids bin are important factors in both safety and practicality. While a larger bin reduces the frequency of emptying, it also increases the physical effort required. A practical balance is a 5-gallon (20L) container, which is manageable for most people.

Material Selection

Wooden compost toilets are common for batch systems but can be affected by moisture. Marine-treated or sealed wood and proper ventilation are recommended to prolong the life of the structure.

Wooden composting pile structures should be separated from the timber frame with straw, hay, or similar insulation. This protects the wood from decomposition by carbon-hungry bacteria, maintains internal warmth, and allows airflow.

Easy-cleaning surfaces such as plastic or ceramic are ideal, as they do not absorb odors or moisture. Fiberglass and textured wood can make cleaning more challenging.

Concrete can be used for floors or compost chambers but is susceptible to pitting and corrosion from urine and humic acids. Applying an acid-resistant sealer, such as silicone or epoxy, can help prolong its life.

Conveyance Methods for Centralized or Split Systems

For split or centralized systems, moving solids from the toilet to the composting chamber is critical. Conveyance options depend on system design and user needs.

Straight Drop: The simplest method, using gravity to move materials down a pipe from the pedestal directly into the chamber. A large-diameter pipe (12” minimum) is recommended to reduce contact, though some cleanup is inevitable.

Micro Flush / Foam Flush: Minimizes liquid transfer into the composting chamber while sealing odors. These pipes often require steeper gradients than standard plumbing, which can complicate retrofitting.

Aquatron Separator: This innovative device separates flush water from solids without moving parts, allowing conventional plumbing to be adapted to a composting toilet system.

Liquids Management

Managing liquids is probably the most important component to consider for proper composting. Excess moisture can lead to anaerobic conditions, causing odor and methane generation. Moisture management also affects the temperature and microbial activity in the compost.

Leachate refers to any liquid that drains through the compost pile. Because it is contaminated with feces, it should be treated as black water. Unlike source-separated urine, leachate cannot be added to greywater systems.

Urine diversion is a common technique to separate liquids at the source. This reduces odor, prevents anaerobic conditions, minimizes the need for additional cover material, and allows urine to be used as fertilizer.

The addition of carbon-rich, composting toilet medium is also incredibly important. These materials balance nitrogen in the feces, trap oxygen in the pile, and physically cover the solids to reduce odor. Woody cover materials are particularly effective, though they decompose more slowly, which is why if you put toilet paper in a composting toilet, it may remain visible for some time.

Maintaining aerobic conditions requires proper ventilation, either with fans in self-contained units or via airflow through outdoor piles or pallets. Temperature control is also crucial: thermophilic conditions (55–60°C) deactivate pathogens, while lower mesophilic conditions require 12–24 months of maturation.

Composting Toilet System Size & Cost

Proper sizing depends on:

- Number of users: Estimate maximum occupancy

- Frequency of use: Heavy or regular use requires larger systems

- Waste capacity: Calculate daily production per person and multiply by users

Cost ranges:

- Batch / external compost pile systems: very low

- Self-contained units (like Cuddy): $300–$2,000

- Centralized or continuous systems: $4,000+

Additional considerations: Greywater systems can handle water from laundry, bathing, and dishwashing, but should not treat leachate, which must be treated as black water.

Vermiculture / Tiger Toilets

One honorable mention we should briefly cover is the vermiculture toilet. These systems incorporate worms, sometimes referred to as tiger or tiger worm toilets, to accelerate the breakdown of solids. While not strictly composting toilets, they are effective in reducing volume and speeding decomposition. Vermiculture toilets are particularly useful in smaller-scale or off-grid applications where rapid breakdown is desired.

How Long to Compost & Safety

The required composting time depends on system type and temperature:

Thermophilic conditions:

- 1 hour at >70°C at the coolest area of the pile

- 3 days at ≥55°C at the coolest area

Mesophilic conditions:

- 18–24 months at lower ambient temperatures

Safety testing: A practical method is the tomato seed test. Hardy tomato seeds are added to the compost along with feces. If seeds fail to germinate, parasitic eggs have likely been destroyed, indicating the compost is safe for use.

Is a Composting Toilet System Right for You?

Composting toilet systems offer a practical, eco-friendly, and often cost-effective way to manage human materials safely, whether you’re living off-grid, retrofitting a tiny home, or simply looking to reduce water use.

While they require thoughtful planning, proper maintenance, and a bit of hands-on involvement, the rewards are clear: odor-free sanitation, nutrient-rich compost for your garden, and a smaller environmental footprint.

By understanding the types of systems, design considerations, liquids management, and composting process, anyone can successfully implement a composting toilet system that meets their household’s needs and supports a more sustainable lifestyle.

What is a waterless composting toilet system?

A system that does not use flush water; conveyance may be manual, gravity-fed, or via split system.

Is a composting toilet system worth it?

We’re a little biased, but yes! Composting toilets are reliable, safe, eco-friendly, and cost-effective, though they require some routine maintenance.

How can I tell if my compost is safe?

Extended composting, thermophilic conditions, and tomato seed tests can verify pathogen attenuation.

Do composting toilet systems smell?

A properly set up and maintained composting toilet should not smell.

Are composting toilet systems legal?

Always check with your local municipalities to ensure that a composting toilet system is legal to install or use on your land. Some municipalities require the use of a septic or city sewer system.

Is a composting toilet system considered a dry flush toilet?

Any toilet that does not use water to “flush” waste can be considered a dry flush toilet.

Do composting toilet systems need water?

No, they are dry toilets, which means they do not need water to function properly. That’s one of the many benefits of using a composting toilet system!